ZEKAN cable manholes

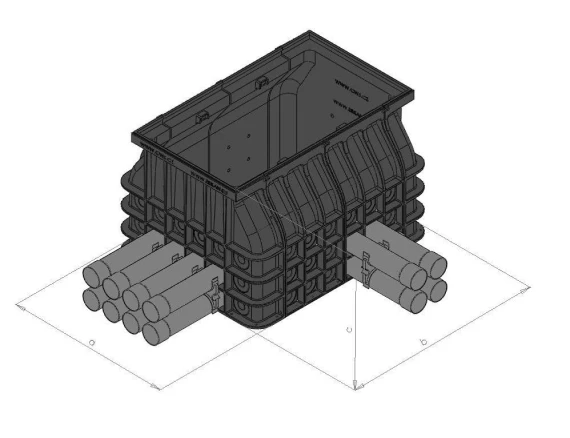

ZEKAN cable manholes are used in the construction of cable ducts as access points for the installation of elements, crossing, branching and cable inspection. Other utility-network elements can also be installed within them. Compared to concrete or masonry manholes, they are considerably lighter as the parts are made of HDPE. They can be installed quickly and easily and, due to the modular system, they enable the flexible change of the manhole size according to the project or construction requirements. Their mechanical load capacity is high, corresponding to the parameters of ČSN EN 124.

The pre-moulded holes for the protectors in the cable manholes are at the same spacing as the protectors in the spacers. The protector outlet holes from the manhole are easily created with a hole saw drill bit for the required protector diameter.

The manholes are supplied with covers with load class B 125 and D 400. The cover lids are made of cast iron and are housed in steel frames. The covers in class B 125 are installed directly on the manhole body. According to the installation instructions, concrete needs to be poured under the D 400 class covers to form a concrete lifting ring to ensure the required mechanical strength. The covers are designed for load class D 400 in a travel surface environment, they are not intended for heavy traffic in exposed locations. If in-paving covers are required, they can be supplied – the lids and the perimeter of the manhole are fitted with stainless steel frames at the required height (according to the paving used). In-paving covers can be supplied if required – the lids and the perimeter of the manhole are fitted with stainless steel frames at the required height (according to the paving used).

As standard, the manhole parts are pre-moulded with grooves for pipe outlets up to Ø 110 mm. For outlets of Ø 160 and Ø 200 mm pipes, the lower part of the chambers can be fitted with parts prepared for these diameters. This is a modular system. Manhole base height: 800 mm.

The base height can be increased by adding parts – extension in 280 mm increments

Installation and concreting of manholes must be carried out according to static reports.

For designers

In order to support the design of the cable manhole system, we had a renowned design office dealing with the structural stability of underground constructions prepare structural reports for all types of ZEKAN cable manholes, which allow simplified design of the appropriate type of manhole for the given solution. This report also includes detailed installation procedures. Simply select the type of manhole, the required load class according to European standard EN 124, and include this file in the implementation and approval documentation. In addition to the procedures according to EN 124, the report also includes the calculation and installation procedure for placing the manholes on the railway according to SŽDC railway regulation S3.

Development

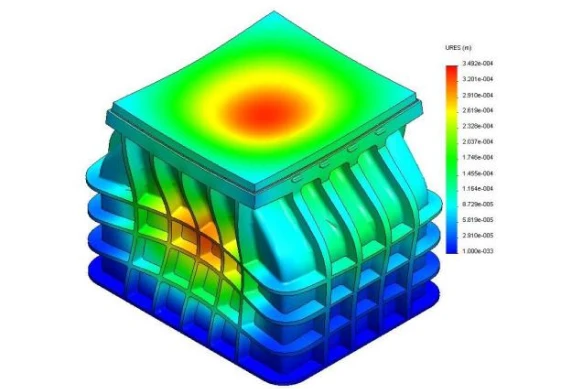

As part of the development, a 3D model of the existing, most common cable manhole system available on the market was accurately dimensioned and constructed to compare the resistance of the assemblies under continuous static loading. The entire design was developed in a 3D environment so that weaknesses in the system could be identified early in the development phase.

Unique resistance to deformation

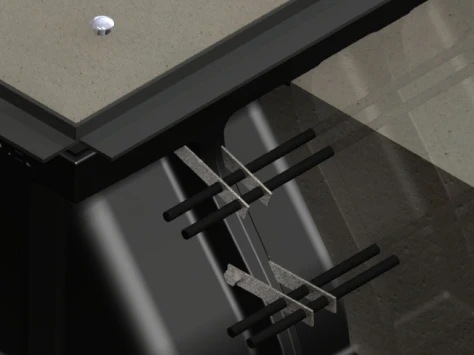

Protection with a unique system of manhole component anchoring at the joints using a system of anchors and standard reinforcing bars ensures maximum protection against lateral soil pressure and, ultimately, the stability of the entire structure throughout its service life, even in the most demanding applications when a simple assembly procedure is followed. The entire system has been developed to reduce the cost of the work and materials associated with the installation of cable manholes.

Other innovative system solutions

The construction of ZEKAN cable manholes is the result of several years of communication with designers, installation companies and utility network construction investors. As a result, the system offers several innovative engineering solutions, some of them protected by the patent office:

- the support frame for the cover is located outside the walls of the cable manhole system components to enable the pouring of concrete under a spreader ring for higher load classes

- in-pressed INSERTS with M12 thread for easy installation of additional accessories (DIN rails, treads, support structures)

- M10 fastener holes located in close proximity to the ribs for maximum system strength

- perimeter support ribs reinforced to twice (joints to three times) the normal thickness to allow for high structural loads

- prescribed shape on the inner wall of the part to accommodate a standard steel profile to prevent wall deformation under high lateral pressure.

Standardisation

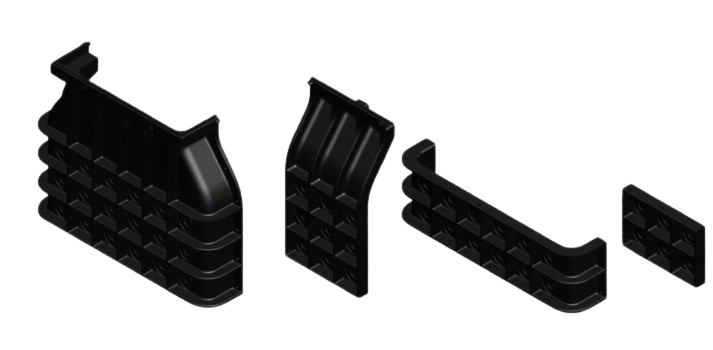

Just 4 basic parts and 4 cover types according to load class are enough to assemble any ZEKAN cable manhole from type S to type XXL. Thanks to this and the universal use of this system, inventory planning is easier, storage and transport costs are significantly reduced by increasing the turnover of this range and reducing the total resources tied up in warehouse stock.

Systemicity

The system is ready for easy installation of cable protectors up to ø 110 mm (moulded parts are prepared for larger diameters) without disturbing the statics of the whole structure. Different types of protectors can be selected according to strength, fire resistance or colour requirements.

Certificate cable manholes ZEKAN

Cable manholes ZAKAN - description

Dimensions of spacers

Cable duct installation technology using ZEKAN cable manholes

Drawings of parts cable manholes ZEKAN

Drawings cable manholes ZEKAN

PVC cable ducts ZEKAN - product sheet

Cable manholes - assembly procedure

Product sheet Cable manholes ZEKAN

DWG drawings cable chambers ZEKAN

DWG drawings cable chambers ZEKAN - parts

DWG drawings cable chambers ZEKAN GRANDE

Drawings cable chambers ZEKAN - parts

Drawings cable chambers ZEKAN GRANDE