Development

The latest software tools for product design, construction and testing were used in the development of the cable chambers.

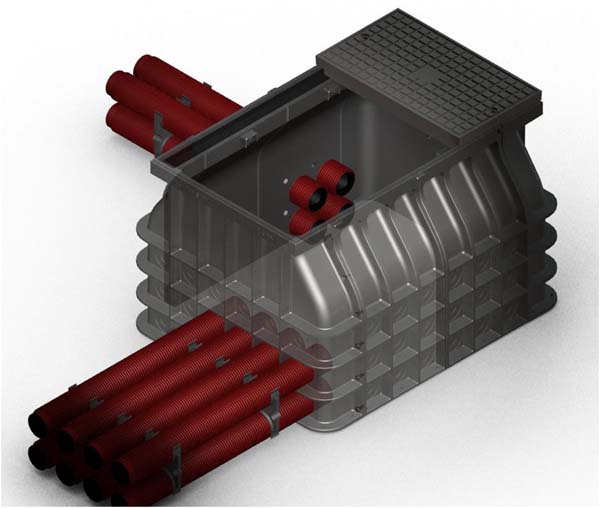

The entire design was processed in a 3D environment in order to identify, as accurately as possible, the weaknesses of the entire design.

The model was compared in this environment with an exact model of the most affordable equivalent solution currently available on our market. The basic requirement for the solution itself was to significantly exceed all relevant parameters of the new system, compared to the competing solution.

By optimizing the shapes of the system parts, the resulting solution showed more than 3 times higher load capacity in a 3D environment compared to the competition.

The finished models then served as the basis for the mould design to ensure maximum accuracy and functionality of the entire cable chamber system.

Both TUL in Liberec and other capacities from the range of experts in the field of plastics technology, statics of building structures and installation companies actively participated in the development of the system design, as well as in the design of the technology used.Another cooperation is on the upcoming Zekan multi-channel system.

Innovation

Thanks to the technical design of the parts, which are protected by the patent office, the system offers a wide range of applications with its simplicity.

- Supporting frame for mounting the hatch outside the walls of the cable chamber system components for the possibility of concreting the spreader ring for higher load classes

- ted cable chamber inlet hem wall for the possibility of placing a steel profile for higher resistance of the assembly while maintaining the possibility of using the standard supplied hatches

- Flush-mounted INSERTS with M12 thread for easy installation of additional accessories (DIN rails, running boards, support structures)

- Preformed shape on the inner wall of the part to accommodate the standard steel profile, as a prevention against wall deformation under high lateral pressure, etc.

Advantages

Standardization – only 4 basic parts and 4 modified hatches according to load class are enough to assemble any ZEKAN cable chamber from type S to type XXL. Thanks to this and the universal use of this system, inventory planning is easier, storage and transportation costs are significantly reduced by increasing the turnover of this assortment and reducing the total resources tied up in inventory (as opposed to less variable solutions).

Systematic – for easy installation of cable protectors up to 110 mm diameter (for larger diameters, shaped parts are prepared) without disturbing the statics of the entire structure.

Different types of protectors can be selected according to strength, fire resistance and colour requirements.

Low transport costs – example: the ZEKAN L 1080 assembly for transport:

- Volume of assembled assembly – 1,38 m3

- Volume of the assembly ready for transport – 0.59 m3

As part of the support, a set of technical reports, assembly and installation procedures, technical solutions for non-standard installations, etc. are prepared and continuously updated, all for maximum simplicity in choosing the right solution.

CWS staff is ready to respond to any question, request, inquiry.